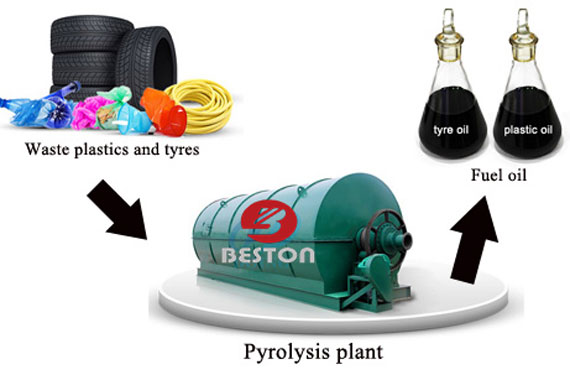

We utilize Beston waste pyrolysis plant to convert waste into useful resources, so the most important issue we pay attention to is the oil yield.

The following is the approximate data for your reference:

| Raw materials | Oil yield | Steel wire | Carbon black | |

| Waste tire | Truck tires | 45%-50% | 15%-20% | 30% |

| Car tires | 40% | 10%-15% | 45% | |

| Bicycle/motorcycle tires | 30%-35% | 5%-10% | 10% | |

| Rubber cable | 25%-35% | |||

| Sole of shoes | 25%-35% | |||

| Mixed sole | 20%-30% | |||

| Waste rubber | Sneakers | 20%-30% | ||

| Waste chemical fiber carpet | 30% | |||

| PMMA | 40% | |||

| Miscellaneous rubber | 35% | |||

| PE | 85%-95% | |||

| PP | 80%-90% | |||

| PS | 80%-90% | |||

| ABS | 40% | |||

| Pure white plastic | 60%-70% | |||

| Fishing net, safety net | 45%-70% | |||

| Waste plastic | Bags of instant noodles | 40% | ||

| Plastic trademark | 20% | |||

| Paper mill scraps | 20%-30% | |||

| Household garbage | 30%-50% | |||

| Pure plastic cable | 60%-80% | |||

| Clean plastic bags | 50% | |||

| Sinking materials | 50% | |||

Methods to improve oil yield:

Beston pyrolysis plants have adopted special methods to improve the average oil yield:

1. Compared with the general condensers, our new-type tubular condenser has the features of larger cooling area and better cooling effect, which can can further ensure and improve the oil yield efficiency.

2. We can provide you with special catalyst, which can not only improve the flavor and color of the oil, but also accelerate the reaction speed. Thus, it can increase the average oil output by 5%.