Waste tires like waste plastics, which is a kind of polymer compound as well as large molecular organic matter. So we can get useful small molecules (oil, gas substances) by interrupting its macromolecular structure.

Rubber is rich in carbon and hydrogen, so waste scrap tire is a kind of material with high calorific value. The calorific value per kilogram is 69% higher than wood, 10% higher than bituminous, 4% higher than coke. If pyrolysis tires by heating and breaking down, we can get a variety of low molecular hydrocarbons, which can not only replace parts of coal, oil, natural gas, but also access to parts of chemical raw materials.

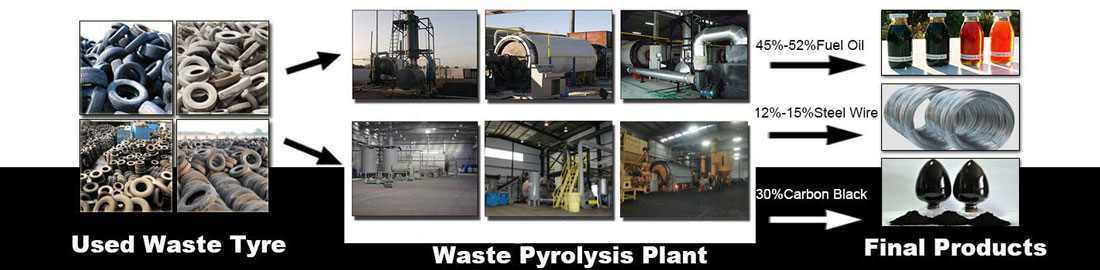

Recycling waste tires by pyrolysis process is a beneficial option. Pyrolysis of waste tires consume waste, and there is no emission of pollutants. It can be also used to recover carbon black, fuel oil and other oil products and chemical products, which is conductive to the environment protection and resources recovery, use and has high economic benefits. It is considered as one of the best methods to dispose waste tires.

After heating decomposition treatment, waste tires are decomposed into oil, combustible gas and carbon powder. The characteristics of the fuel oil generating from thermal decomposition is similar to the commercial fuel oil. It can be directly used for burning or using by mixed with fuel oil extracting from petroleum, as well as can be used as rubber processing softener. The resulting combustible gas is mainly consist of hydrogen and methane, which can be used as fuel materials or burned in place to meet the needs of the pyrolysis process. The resulting carbon powder can replace carbon black or processed into a special adsorbent. In addition, steel wire is also a final product after thermal decomposition.

The main components of the pyrolysis gas are methane, ethane, ethylene, propane, propylene, acetylene, butane, butene, 1,3-butadiene, pentane, benzene, toluene, xylene, styrene, carbon monoxide, carbon dioxide and hydrogen sulfide, etc. The main gas distribution is ethylene, followed by propylene, butene, isobutylene and so on. The calorific value of the pyrolysis gas is equivalent to natural gas and can be used as fuel. The carbon black from tyre pyrolysis can be used as low-grade rubber products to strengthen the filler or used as pigment of ink, or used as fuel for directly burning; in addition, because the carbon residue contains refractory sulfide, sulfate and inorganic salts, metal oxides added in rubber processing process as well as mechanical impurities, it can be directly applied to the production of rubber molding; moreover, if mixed with ordinary wear-resistant carbon black according to a certain ratio, the wear resistance will be greatly enhanced. The pyrolytic carbon black, pickled carbon black surface contains a large number of ester groups, chain hydrocarbon grafting, therefore it has different surface characteristics of pigment carbon black. The surface polarity of recycled carbon black is lower than pigment carbon black. This feature increases the surface lipophilic properties of recycled carbon black and has better dispersibility as a new-type carbon black applied to rubber, ink and other materials.

Through the analysis, the tyre pyrolysis oil (a mixture of paraffins, olefins, aromatics) has a high calorific value of about 43 mJ / kg and can be burned directly as fuel or as supplementary feeding for refineries. Because the main ingredients of the product are benzene, toluene, xylene, styrene, dipentene and trimethylnaphthalene, tetramethylnaphthalene and naphthalene, they can be also used as a source of chemical. These compounds are useful chemical raw materials.