Waste plastics and waste tires are called “white pollution” and “black pollution”, and the countries around the world are actively seeking the scientific approaches. In the recent years, waste plastic/tire pyrolysis technology and equipment has received extensive attention.

In the area of waste plastic/tire comprehensive utilization, we have formed four main methods: waste tire refurbished re-manufacturing, production of reclaimed rubber, plastic waste landfill and pyrolysis. But the former three ways only take use of less than 1% prototype. Tire refurbished has operability only in the case of tire without damage; rubber powder machine needs energy-intensive equipment under low temperature freezing conditions; the production of reclaimed rubber consume too much energy; plastic waste is difficult to degrade, and landfills take up a lot of land resources. So many western countries have already eliminated this approach.

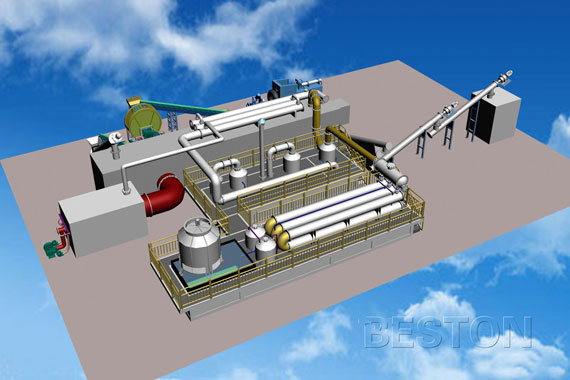

In the recent years, China Beston has done a lot of researches in waste plastic/tire continuous pyrolysis comprehensive treatment technology and complete set of equipment, including the development of the equipment, optimization of process conditions, which has ensured the tightness of operation system, and can effectively reduce pollutant emissions and achieve production standardization, scientific, environmental protection, industrialization. The benefits and unique advantages of the continuous waste plastic/tire pyrolysis equipment have brought about more and more attention.

The characteristics of Beston continuous pyrolysis plant are high heating speed, rapid response, short gas residence time, high thermal efficiency, high oil yield, and also can reduce the occurrence of secondary reactions at the same time. The plant can deal with waste plastic, tire, rubber, medical waste, oil sludge and can achieve non-pollution, continuous, automatic, comprehensive treatment, industrial production. The technology will get wider popularization and application.