Pyrolysis is an advanced thermal decomposition process used to convert waste materials—such as plastics, tires, and biomass—into valuable fuels and raw materials. The success of this process depends heavily on the design and engineering of the reactor itself. A well-designed pyrolysis reactor ensures high conversion efficiency, product consistency, and long-term operational stability. This article explores the key factors to consider in pyrolysis reactor design to achieve optimal results in both industrial and research-scale applications.

1. Understanding the Pyrolysis Process

Pyrolysis involves heating organic materials in the absence of oxygen to break them down into smaller molecules, producing bio-oil, syngas, and char. The process typically occurs between 350°C and 700°C, depending on the feedstock. For example, the operating conditions for a continuous pyrolysis reactor differ significantly from batch systems, as continuous units are designed for uninterrupted operation and higher throughput.

The reactor design determines how efficiently heat is transferred to the feedstock, how gases are collected, and how residues are discharged. Therefore, a clear understanding of thermal dynamics, material flow, and reaction kinetics is essential.

2. Material Selection and Reactor Construction

The choice of construction materials directly impacts reactor durability and safety. Pyrolysis reactors are exposed to high temperatures, corrosive vapors, and abrasive solids. Therefore, materials such as stainless steel (grade 310 or 316) or high-temperature alloys are commonly used. For reactors processing aggressive feedstocks—such as in a plastic pyrolysis reactor—anti-corrosive coatings or refractory linings can further enhance longevity.

Structural design must also account for thermal expansion, insulation thickness, and sealing performance. Any weak point in the structure can lead to leaks or temperature fluctuations, which may compromise product quality or cause safety hazards.

3. Feedstock Preparation and Feeding Mechanism

The physical form and composition of the feedstock influence reactor design. Uniform particle size promotes better heat transfer and predictable reaction rates. Therefore, many systems include preprocessing steps such as shredding, drying, or pelletizing.

The feeding mechanism should prevent air ingress, as oxygen can cause unwanted combustion. In continuous systems, screw conveyors or airlocks are commonly used to maintain an inert environment. Proper feeding design ensures consistent input, reduces downtime, and improves operational safety.

4. Heating Method and Temperature Control

Efficient heat delivery is central to successful pyrolysis. Common heating methods include indirect heating through external burners or direct heating via internal gas circulation. The selected method should ensure uniform temperature distribution throughout the reactor chamber.

Temperature sensors, thermocouples, and automated controllers are critical for maintaining stability. Modern control systems use feedback loops to optimize heating profiles, preventing overheating or incomplete conversion. This is especially crucial for feedstocks like scrap tires, which require precise temperature control for consistent yields in a tire pyrolysis reactor.

5. Gas Flow and Residence Time

The internal geometry of the reactor must support proper gas flow and residence time control. Inadequate residence time can lead to incomplete conversion, while excessive residence can cause secondary cracking, reducing liquid yields. Designers often use computational fluid dynamics (CFD) models to predict and optimize these parameters.

Additionally, incorporating baffles or internal mixing mechanisms helps distribute heat evenly and prevent channeling effects. The goal is to maximize the interaction between the feedstock and the thermal environment without compromising throughput.

6. Condensation and Gas Recovery Systems

A pyrolysis reactor is only part of a complete system. The downstream condensation and gas recovery units are equally important. Condensers must efficiently cool the vapors to recover high-quality oil, while non-condensable gases should be recycled as fuel for heating. This closed-loop approach enhances overall energy efficiency and reduces emissions.

Advanced designs integrate heat exchangers, gas scrubbers, and automated pressure controls to achieve clean and sustainable operation. These systems demonstrate how thoughtful design integration can lead to both environmental and economic benefits.

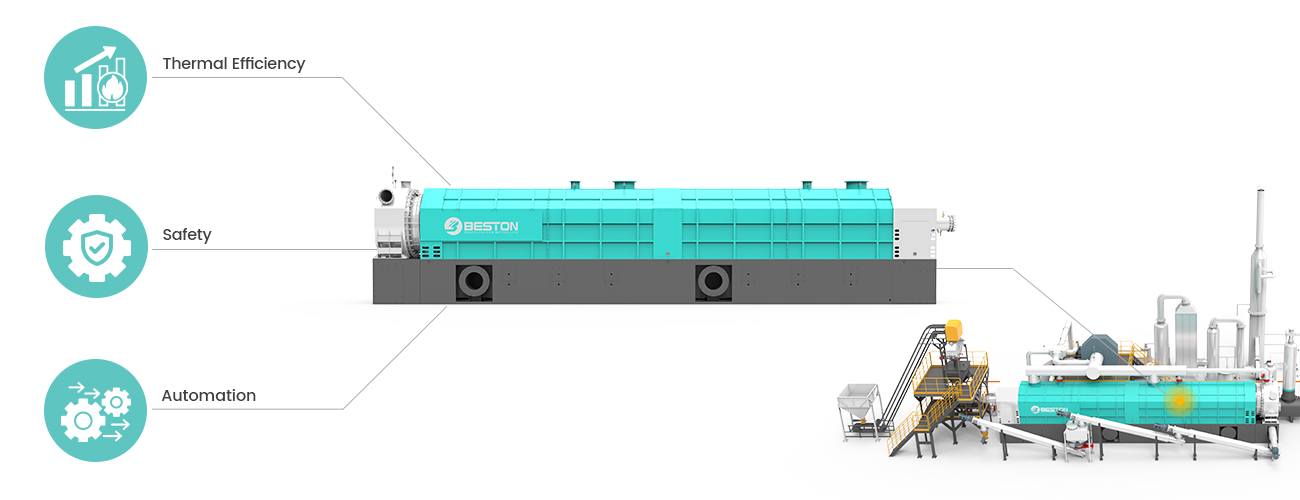

7. Safety Considerations and Automation

Safety must never be an afterthought in pyrolysis reactor design. Since the process operates at high temperatures and under potentially explosive conditions, reliable pressure relief valves, flame arrestors, and emergency venting systems are mandatory.

Automation further enhances safety by reducing human intervention. Sensors continuously monitor pressure, temperature, and gas composition, allowing for real-time adjustments. Advanced control panels can even perform self-diagnostics to prevent malfunction or overheating.

8. Environmental and Regulatory Compliance

Modern pyrolysis reactors must comply with strict environmental regulations. Proper gas treatment, waste handling, and emission control are essential for obtaining permits and community acceptance. Systems with efficient condensers and gas recycling units minimize the release of volatile organic compounds (VOCs).

Design engineers should also consider lifecycle impacts, including energy consumption and the recyclability of reactor components. Sustainable design principles not only support regulatory compliance but also strengthen the business case for investment.

Conclusion

Designing an efficient pyrolysis reactor requires balancing thermal performance, material strength, safety, and environmental responsibility. From material selection and heating systems to gas recovery and automation, every design element contributes to the overall success of the system. With advancements in technology and growing demand for circular economy solutions, pyrolysis reactors will continue to play a crucial role in waste management and renewable fuel production.

By applying these design principles—and learning from proven systems such as those developed by beston group pyrolysis—engineers and investors can build reliable, efficient, and eco-friendly pyrolysis plants for the future.