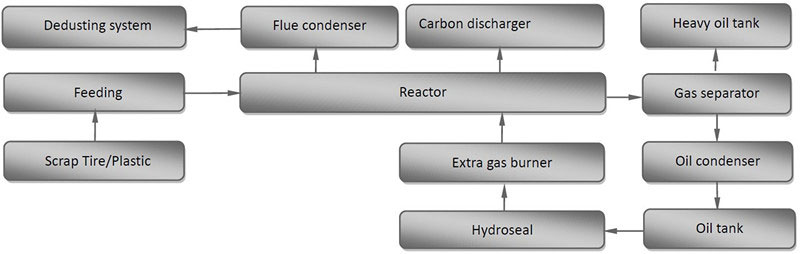

1. Crush waste tires into rubber pieces required for pyrolysis, and then the pieces are fed into pyrolysis reactor along with catalyst through the hot air-tight device for pyrolysis reaction;

2. The pyrolysis oil and gas are fractionated and cooled by the oil separator to produce fuel oil and a small amount of combustible gas (for personal use after purified);

3. The solid products generated from pyrolysis are crude carbon black and a little steel wire. After separated by magnetic separation, the coarse carbon black is automatically transported to the carbon black processing machine and then subjected to a series of treatment processes such as pulverization to obtain industrial carbon black or other high value-added chemical products. The separated steel wire is treated as scrap steel;

4. The fuel gas after purified by the purification system is used as fuel for the heating system. The heating system adopts waste heat recycling way, which greatly saves the energy consumption and reduces the running cost of the equipment. The flue gas generated in the production line is purified by the purification system to meet the emission standards.

1. The mixed waste plastics are crushed and then fed into the pyrolysis reactor automatically through the feeder, and heated initially during the transportation. The low melting point plastic of the PVC is cracked and the HCl is separated from the other materials and neutralized;

2. The raw materials are fed into the reactor continuously and dispersed by the dispersion system. The constant temperature heating system supplies heat for the reactor, and the pyrolysis reaction is completed under the effect of high-efficiency catalyst;

3. The oil and gas from pyrolysis after fractionation, fixed-bed second gas phase catalysis, dewaxing and other processes gets high-quality fuel oil and a small amount of combustible gas (for personal use);

5. A small amount of non-condensable gas generated in the pyrolysis process is purified by the flammable gas purification system to be used as fuel for the pyrolysis system, which can achieve self-heating. The flue gas generated in the production line is purified by the purification system to meet the emission standards.

6. After pyrolysis, there will be a little solid residue left, which can be discharged automatically from the reactor and made into fuel rods for harmless treatment.